CNC machining has changed manufacturing as we know it. It has led manufacturing to shift gears, bring in advanced technology, and create quality goods in safer working environments. CNC machining is a thriving field that is in need of skilled workers—workers who desire to create, innovate, and be a part of the evolving manufacturing field.

If you are interested in a manufacturing career that involves creative, high-tech work, CNC machining could be the perfect fit for you. Of course, you may still be asking, “Why?” Why take this leap into CNC machining? Below we investigate the top reasons to study CNC and pursue a future in CNC machining.

Why Enter the Field of CNC Machining?

CNC is a High-Tech, Cutting-Edge Field

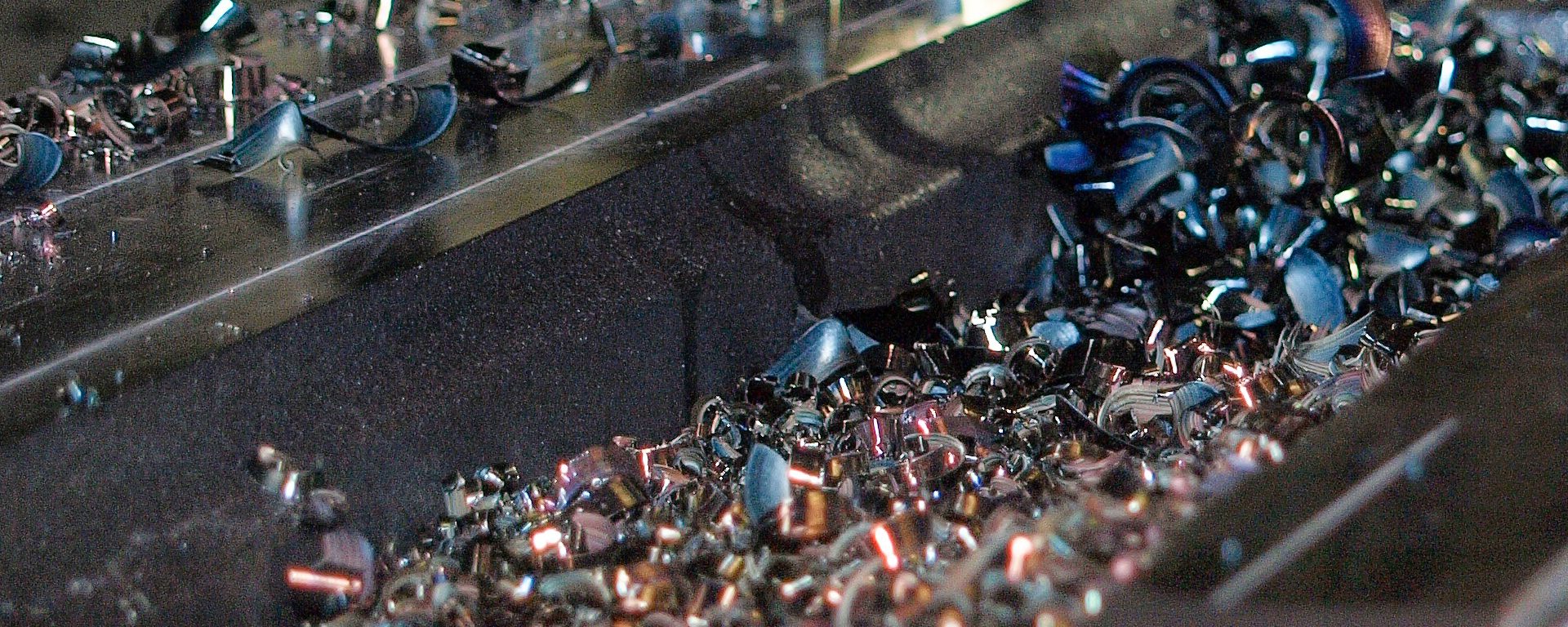

CNC stands for computer numerical control, which is a computerized manufacturing process designed to automate the production of goods. CNC machines are pre-programmed (using software and code) to control the movement of equipment and create products that meet exact specifications. This process ensures the precise, seamless production of goods—and is therefore propelling the future of manufacturing.

If you choose to study CNC machining, you will be entering a highly-technical and innovative field. You will work directly with state-of-the-art machinery, technology, and cutting-edge software. You will be involved in a process in which technology brings ideas to life, and you will be at the forefront of modern manufacturing. As more manufacturers rely on advanced CNC technology to drive production, you can rest assured you will be an essential asset, with an essential skillset, in the workforce.

The Demand for CNC Machinists is High

The CNC machining industry is booming right now. According to recent research, the global CNC machine market is expected to grow 44 percent, or about $35 billion, between 2019 and 2026. This is due to a rising demand for automation, precision, and efficiency in the production of manufactured goods. While many assume that technology might replace hands-on workers, the reality is that the manufacturing field still needs machinists to operate CNC equipment.

This is particularly true in Connecticut, where we are facing a historic shortage of manufacturing workers, as many older employees are entering retirement and there is a lack of skilled workers to fill these jobs. In the first quarter of 2020, Connecticut reached a 10-year high in manufacturing employment—but there are still 8,000 to 10,000 manufacturing positions open for want of skilled candidates. The reason there are so many open positions, according to 40 percent of manufacturers themselves, is that they are struggling to find qualified workers with a foundation of skills/expertise.

By training up in CNC machining now, and entering the manufacturing workforce, you can rest assured that you will find a successful career, as well as have upward mobility in the CNC workforce.

It’s a Creative, Hands-On Career

CNC machining is not your typical desk job. While it does involve computer operation, it also involves a lot of hands-on work. As noted above, CNC machinists have the opportunity to bring ideas to life and create products that will be used every day. They work with CNC programmers to create designs that are practical and innovative. They play an important role in bringing these designs to fruition. For example, in Connecticut, CNC machinists can often be found creating parts that will be used within the aerospace, military defense, automotive, submarine, and medical sectors.

You Can Expect Comfortable Pay

On average nationwide, CNC machinists can expect an average salary of $43,170 annually. In certain states, however, the earning potential is even greater. Connecticut is among the highest paying states for CNC machinists, according to the Bureau of Labor Statistics. In fact, throughout New England, CNC machinists can expect a salary potential of at least $46,000 annually, which is higher than the national average for CNC operators today.

Why Attend a CNC Machinist School?

Get a Competitive Advantage

Many aspiring machinists beg the question, “Why should I go to school for this trade?” If postsecondary education is not required to become a CNC machinist, what is the benefit of attending a CNC machinist school? The truth is, employers prefer to hire candidates with experience under their belts. CNC machinists who have formal training in this field, and who have worked with computer numerical controlled machines, are more likely to be hired over someone just starting out.

According to a prior survey from the Connecticut Business & Industry Association, manufacturers prefer to hire CNC machinists who have experience and relevant, technical training: “For the most part, manufacturers expect new employees to arrive already trained.”

A hands-on CNC machinist training program will help you to advance your skillset in machine operation, and therefore qualify for more job opportunities and higher earning potential. It will also make you stand out amongst the competition, as you will have valuable skillsets in technical drawings, blueprints, manufacturing mathematics, Mastercam software, and computer-aided machine operation.

Professional Certifications are in Closer Reach

A CNC machinist program, whether that be a certificate program or associate degree, can make you eligible for professional certifications in the field. While CNC machinist certification is not required, it can demonstrate your level of expertise and skill in the field – and can therefore position you for growth opportunities down the road.

At Goodwin University, graduates of our CNC training programs are prepared to earn nationally-recognized, portable credentials from the Manufacturing Skill Standards Council (MSSC) and the National Institute for Metalworking Skills (NIMS).

CNC Training Can Be Completed Quickly

If you are hesitant to invest in a CNC college or trade school, it may ease your mind to know that there are flexible programs out there. You don’t need to spend years in manufacturing school to get the training you need. At Goodwin, for example, there are different options for CNC machinist education:

- An 18-credit CNC certificate program, which is just two semesters and can be completed in just a matter of months.

- An accelerated certificate in CNC Machining, Metrology and Manufacturing Technology, which is open enrollment and can be completed in 22.5 weeks full-time.

- An associate degree in CNC machining, which can take less than two years to complete. Most classes are offered in the evenings, for added flexibility.

Study CNC Machining Today

If you are interested in launching a thriving, successful career as a CNC machinist in Connecticut, now is the time to get started. To learn about Goodwin’s different CNC program options, do not hesitate to call us at 800-889-3282. Or, you may visit us online to learn more about our flexible CNC operator school.

Goodwin University is a nonprofit institution of higher education and is accredited by the New England Commission of Higher Education (NECHE), formerly known as the New England Association of Schools and Colleges (NEASC). Goodwin University was founded in 1999, with the goal of serving a diverse student population with career-focused degree programs that lead to strong employment outcomes.