Computer Numerical Control (CNC) machining is a vast, extensive field within the ever-evolving manufacturing industry. Becoming a CNC machinist can offer heaps of growth opportunities for your career, with around 35,400 job openings for machinists projected each year. However, before starting your journey, it’s essential to understand the potential work environments you might find yourself in.

Whether you are drawn to traditional machining or cutting-edge technologies, CNC machining has something for everyone.

What is a CNC machinist?

A Computer Numerical Control (CNC) machinist maintains and operates specialized equipment to produce various metal parts, products, and instruments. Vital to modern manufacturing, these computerized machines help to create things we use every day, yet another cog in the wheel that makes the world go round.

To become a CNC machinist, you’ll need a high school diploma and some training, either on the job or at the postsecondary level. Many individuals choose to complete apprenticeships or enroll in certificate programs at career-focused colleges. After training, students must pass the National Institute for Metalworking Skills (NIMS) certification to demonstrate competency in the field.

To be considered a skilled machinist, you must develop technical proficiency in reading blueprints, understanding machine programming, and troubleshooting mechanical issues. Strong mathematical and problem-solving skills are also crucial for making sure that parts meet specific standards. Beyond this, as automation continues to transform manufacturing, CNC machinists should perfect skills and knowledge in robotics and computer-aided design (CAD) software.

Where can CNC machinists work?

As a CNC machinist, you’ll have the chance to work in various exciting and cutting-edge job environments. While work in traditional manufacturing settings is most common, you may find yourself in other industries such as medical device production and automotive manufacturing.

CNC machinists’ work environment

When asking yourself, “Where do machinists work?”, you’ll have to broaden your idea of what they do, as you’ll find CNC machinists nearly everywhere, working in settings with plenty of industrial movement and activity. For example, according to the U.S. Bureau of Labor Statistics (BLS), machinists can often be found in:

- Metal product manufacturing

- Machinery manufacturing

- Transportation equipment manufacturing

- Wholesale trade

- Employment services

Common industries and workplaces in which CNC machinists operate include:

- Machine shops

- Metalworking shops

- Manufacturing plants and factories

- Aerospace product and parts development

- Railroad rolling stock production

- Engine, power, and turbine facilities

- Electric power generation

- Scheduled air transportation

- Petroleum and coal product manufacturing

- Natural gas distribution

No matter the work environment, the CNC job involves a variety of technical skills, such as setting up machines, monitoring production, running diagnostics, and problem-solving when things go awry. To put it simply, CNC machinists can be found bringing pieces of metal into working parts and products that we use regularly. They read blueprints, run software programs, operate computerized production equipment, measure and test products, and more to create quality goods.

Machinists also collaborate with engineers and designers to refine processes and improve production efficiency. With advancements in automation, CNC machinists may oversee robotic systems that handle repetitive tasks, allowing them to focus on precision and quality control.

Learn more about the responsibilities of a CNC machinist.

Types of CNC machines

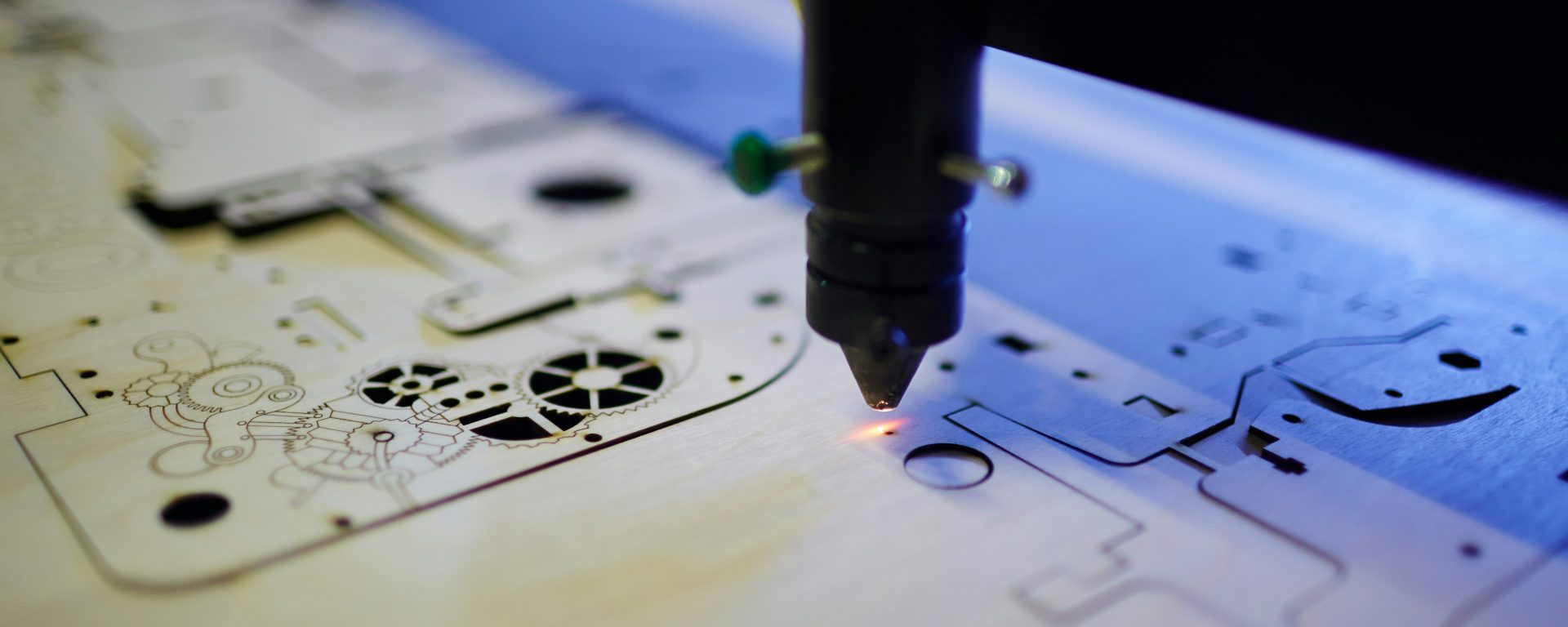

CNC machinists can specialize in different types of machines to enhance their expertise in the manufacturing industry. Some standard CNC machines include:

- CNC Electrical Discharge Machines (EDM): Used for intricate and precise cutting by eroding material with electrical discharges

- CNC Lathes: Used for turning operations

- CNC Milling Machines: Used for cutting and drilling operations

- CNC Plasma Cutters: Used for cutting metal using a plasma torch

- CNC Routers: Used for cutting various materials like wood, plastic, and metal

Types of CNC machinists

CNC machinists take on a lot of interesting roles, each with different responsibilities and skill requirements. Here are some common positions in the field that give insight into the CNC machinist work environment:

- CNC Operator: Responsible for loading stock material into machines and running production parts. This is often an entry-level position, as it does not require adjusting machine specifications or handling complex tasks. These individuals typically work in manufacturing and industrial settings, like electronic and semiconductor plants and woodworking factories.

- CNC Setup Operator: Prepares machine programs, sets up tools, tests programs, and ensures that parts function correctly. This role also involves troubleshooting and fixing issues that may arise. Setup Operators can find work in metal fabrication shops and medical device manufacturing.

- CNC Programmer: Reads and interprets blueprints to determine manufacturing processes. They write programs to generate specific parts and select the appropriate tools for machining. Individuals in this discipline can work in industrial equipment manufacturing and aerospace companies.

- CNC Quality Control Specialist: Inspects and tests finished products to meet industry standards and customer specifications. This role is crucial for maintaining high production quality. Quality Control Specialists commonly work in production environments, automotive manufacturing plants, and defense companies.

Start your CNC machining journey at Goodwin.

Manufacturing industry job outlook

As technology continues to advance, skilled CNC machinists remain in high demand. Students who master advanced machining techniques and refine their craftsmanship position themselves as unique job candidates for employers.

The increasing use of automation and smart manufacturing is revolutionizing the industry. New advancements create opportunities for CNC machinists to grow and develop in their careers. Those who understand data analytics, machine learning, and cloud-based manufacturing systems will have an advantage in the evolving industry.

Experienced CNC machinists can earn over $75,000 per year, making this a lucrative career choice. Additionally, most machinists become skilled in programming, operating, and maintaining various types of CNC machines. Stay sharp! Professionals in this field must continually update their skills and adapt to new software and hardware advancements.

Grow your career as a CNC machinist

CNC machining is the gift horse that keeps giving—a field that allows professionals to develop their skills while contributing to producing essential tools and instruments. However, success in this industry requires strong attention to detail, high accuracy, and exceptional problem-solving skills.

Obtaining machining certifications and staying updated on industry advancements can help set you apart from your peers. Many CNC machinists pursue additional certifications to further refine their skill set. Areas such as advanced manufacturing technologies, robotics, or specialized machining techniques can enhance your career prospects.

There’s no single answer to the question, “Where do machinists work?” Because, with the right training and experience, you can work practically anywhere, advancing to supervisory or engineering roles, overseeing production processes, and contributing to innovation in manufacturing.

Learn more about manufacturing programs at Goodwin University to see if CNC machining is a good career choice for you!

Goodwin University is a nonprofit institution of higher education and is accredited by the New England Commission of Higher Education (NECHE), formerly known as the New England Association of Schools and Colleges (NEASC). Goodwin University was founded in 1999, with the goal of serving a diverse student population with career-focused degree programs that lead to strong employment outcomes.