We have seen the growth of the manufacturing industry increase and evolve with new, cutting-edge technology in the fields of Computer Numerical Control (CNC) Machining and Robotics.

Computer Numerical Control machines make durable goods like aircraft and cars. In contrast, robots are being used to assist in surgery, on companies’ manufacturing floors, and even in the day-to-day operations of sales teams.

Keeping up with technological advances can be challenging, so manufacturers rely on skilled, qualified, and trained technicians to operate, develop, and maintain these machines.

Let’s explore the similarities and differences between a CNC machining and Robotics career to determine which degree or certificate best aligns with your talents and goals.

What is CNC Machining?

CNC Machining is an automated subtractive manufacturing process where an object is shaped by removing material from a workpiece until the desired shape is achieved. This process uses computerized software to control how the machines move and operate.

An algorithm, written by designers, instructs the machine where to move and how to operate and control other secondary processes. CNC machines generally only move in the X, Y, and Z axes and are precisely controlled by a computer.

These highly accurate processes, in turn, allow the machines and machinists alike to deliver superior versatility, efficiency, and precision when making everything from small electronic components to large-scale aircraft parts.

What Do CNC Machines Do?

CNC machines range from small milling machines primarily used for milling, drilling, turning, and cutting to large, high-powered units controlling multiple devices across as many as five-axis ranges.

Widespread types include:

- CNC milling machines

- CNC plasma cutters

- CNC lathe machines

- CNC laser-cutting machines

- CNC drilling machines

All of these machines have specific purposes and jobs, and machinists choose based on the accuracy required, the budget, and the time available to complete the job.

Where Do CNC Machinists Work?

CNC machinists and operators succeed tremendously in today’s in-demand machining job market. According to the U.S. Bureau of Labor Statistics (BLS), machinists earn a median annual salary of $47,940, and about 44,100 job openings are projected annually.

After obtaining their CNC degree or certificate, candidates go on to exciting careers and positions such as:

- CNC machine programmers

- CNC machine set-up

- Lathe and Mill CNC machinists

- Lathe and Mill CNC operators

- Manual machine operators

How Do You Become a CNC Machinist?

Students can enroll in certificate and associate degree-level programs to embark on this rewarding career. Both programs integrate an understanding of the manufacturing processes, knowledge of materials, and a working comprehension of manufacturing mathematics. Students can also expect to gain competence with technical drawings, specifications, and computer-aided machining.

While training programs differ depending on the school or university, many certificate programs can be completed in as little as one year. An associate degree in CNC Machining can be earned in as little as two years.

Ready to take the next step toward becoming a CNC Machinist? Download our Get Start Guide to discover how Goodwin University can help you get there!

What is Robotics?

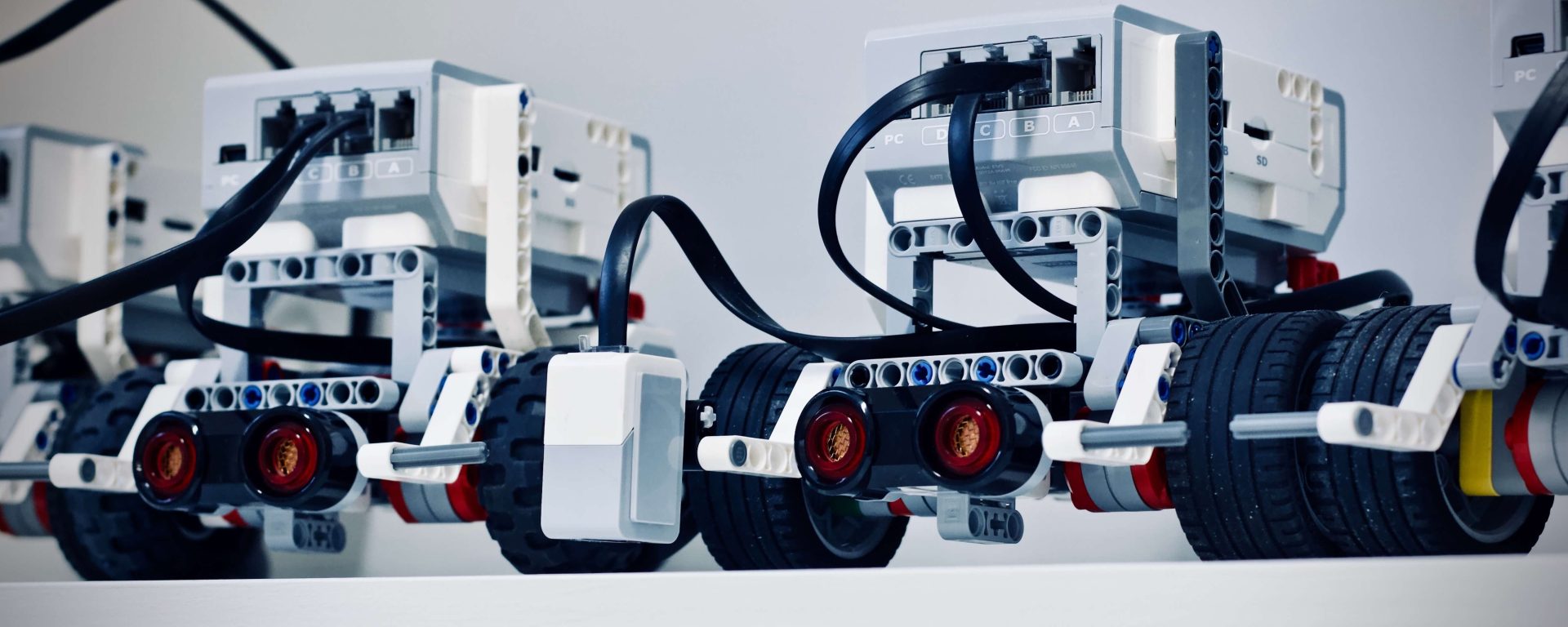

Robotics, a multidisciplinary field, combines artificial intelligence (AI), computer science, and engineering to design and create robots that perform tasks to aid and, sometimes, replace humans.

Almost all industries, such as the automotive, healthcare, information technology, AI, and virtual reality (VR) industries, use robotic machines and technologies to make life simpler and safer.

Unlike inflexible CNC machines with stiffness in their axes, robots are highly flexible and can accomplish various tasks.

What Can Robots Do?

Robots are powered by precisely-controllable motors for almost any task imaginable, though there are still practical limitations to the technology.

These tasks include:

- Machining. Robots can do many, but not all, of the same tasks as CNC machines.

- Pick and Place. Robots can move objects around a workspace.

- Welding. Robots can weld in various settings, including spot, arc, and resistance welding.

- Sorting. Unlike CNC machines, robots can use sensors to detect the object type before sorting objects into different groups.

- Painting. Not just painting with traditional paint and brush, this movement describes any processing task where a robot moves a tool along a repetitive up and down or side-to-side motion.

Simply put, a single robot can complete many tasks, whereas CNC machines offer high performance for specific machining tasks.

What Does a Career in Robotics Look Like?

Like CNC machining, the use of robotics is growing, and candidates find work in a variety of fields and positions, including:

- Robotics researchers

- Artificial intelligence robotics engineers

- Robotics engineers and technicians

- Robotics deployment

- Prosthetics engineers

- Electro-mechanical technicians

The U.S. Bureau of Labor Statistics reports that candidates who operate, test, and maintain robotic equipment, can expect to earn a median annual salary of $60,360 per year.

How Do You Begin a Career in Robotics?

Due to the comprehensive and computer-centric duties of robotics technicians, candidates often must be well-trained with a postsecondary education and training program like robotics and automation, electrical engineering, or manufacturing technology.

Robotics and Automation Technician Training programs introduce and provide students with an understanding of motor and programmable controls relating to the automation process and the basics of maintaining, troubleshooting, and programming automated systems.

Programs typically take two to three semesters to complete, and many universities, like Goodwin, offer students flexible part- or full-time options.

Whether you are passionate about robots or interested in a career in CNC machining, our faculty and staff at Goodwin University are ready to support and offer hands-on operational experience in our Robotics and CNC Machining programs.

Together, we’ll get you through college and into the rewarding, in-demand field of your choice. Learn more or apply today—applications are open, and various financial aid opportunities are available.

We’re ready when you are!

Goodwin University is a nonprofit institution of higher education and is accredited by the New England Commission of Higher Education (NECHE), formerly known as the New England Association of Schools and Colleges (NEASC). Goodwin University was founded in 1999, with the goal of serving a diverse student population with career-focused degree programs that lead to strong employment outcomes.