If you’re interested in joining the manufacturing workforce, you may be curious to learn more about machining and – more specifically – precision machining. Precision machining is an evolving area of manufacturing, and something that impacts our daily lives. As a result, it is a key contributor in the field today. But what is precision machining, exactly, and how do you get involved? Let’s explore this growing field and how, precisely, you can launch a machining career.

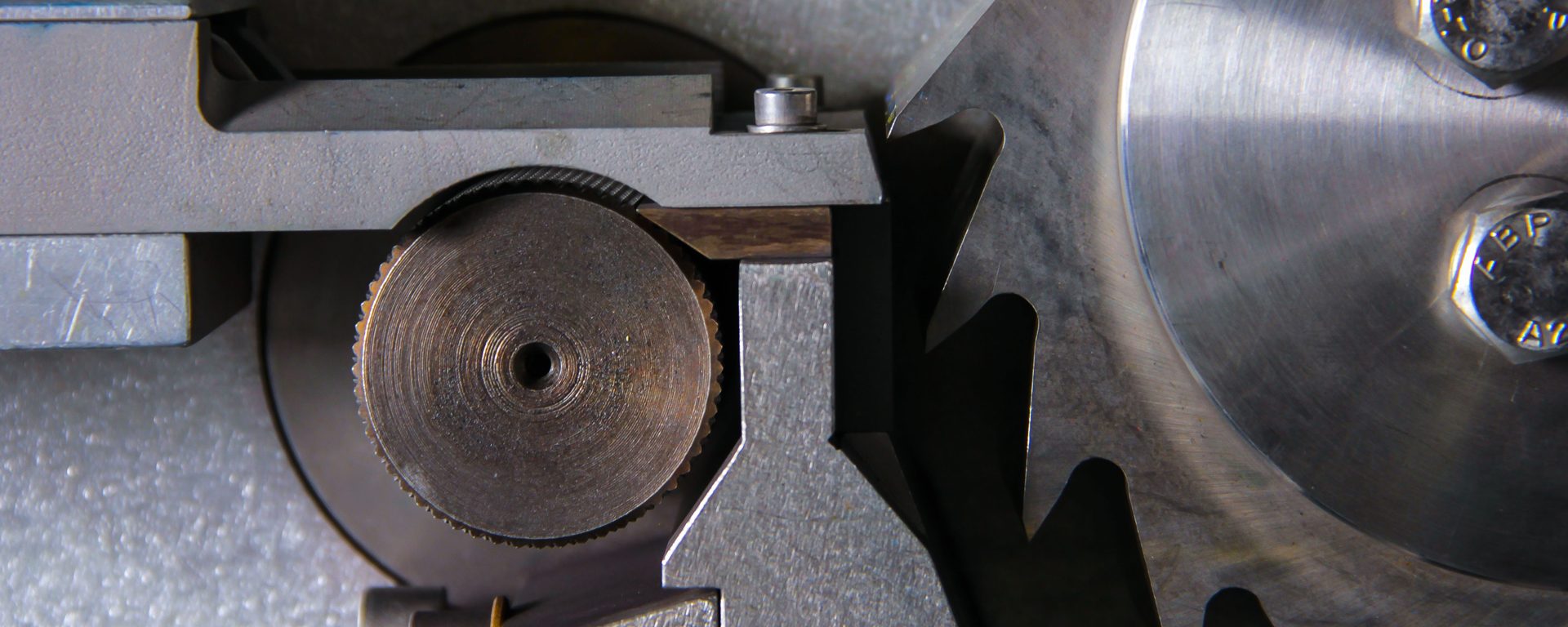

Precision machining is a process that removes excess, raw material from a work-piece, while holding close tolerance finishes, to create a finished product. Simply put, it means shaping large pieces of material into more precise parts, so that they can meet very exact specifications. This process involves cutting, milling, turning, and electrical discharge machining, and is generally performed using Computer Numerical Control (CNC) equipment.

Precision machining produces quite a bit of both large and small objects that we use in everyday life. Believe it or not, every little piece of an object requires some level of a machinist’s skills. Likewise, a tool or machine that has been worn down will often require machine tool calibration, welding, or grooving by a precision machinist. From the production of automobiles to surgical devices and aircraft parts, precision machining is involved in every technology and industry. So, basically – if a product contains parts, it required some precision machining.

Successful precision machining requires the ability to follow extremely specific blueprints made by Computer Aided Design (CAD) or Computer Aided Manufacturing (CAM) programs. This CNC machining technology creates 3D diagrams or outlines needed in order to produce a machine, object, or tool. The blueprints must be created with great detail to ensure quality and success.

While most precision machining companies work with some form of CAD/CAM programs, they still often work with hand-drawn sketches in the initial design phase.

Precision machinists work with a variety of materials such as bronze, glass, graphite, plastics, steel, and other metals. Depending on the size of the project and the materials involved, various precision machining tools and techniques will be used. Machinists must, then, be well-versed and experiences with these different processes and equipment. They may use any combination of drill presses, grinders, lathes, milling machines, saws, and even high-speed robotics to get a job done.

Precision machining is a bucket within the CNC machining and programming field. Therefore, to land a career as a precision CNC machinist, you must have a working knowledge and skill in CNC technology.

It is not always enough to be able to “run” a machine. Modern employers prefer certified, trained, and educated CNC machinists to join their working teams. As a leading manufacturing school in Connecticut, Goodwin College is always keeping up with what employers are looking for. Our Bachelor’s, Associate’s, and Certificate-level manufacturing and machining programs prepare students for an exciting industry – one that is driven by technology, innovation, and creativity. Not only will you learn the skills needed to compete in the fast-paced world of precision CNC machining, you will master:

- Excellent communication skills

- Working well with people of diverse backgrounds

- Problem-solving abilities of today’s successful manufacturing professionals

Goodwin’s CNC machinist training combines classroom instruction and hands-on operation, using state-of-the-art technology. Our new CNC 3-axis milling and turning machines will give you the skillsets and machining experience needed to be successful in the industry. You’ll also gain competence in:

- Technical drawings

- Material properties & metal working theory

- Product specifications

- Computer-aided machining

- CAD and CAM software

Our CNC programs are flexible and work well for working students. While class schedules vary by course and semester, many CNC machining classes are offered at night and even select weekends. The majority are available on-campus, while some in a hybrid, online format. Some CNC programs, such as our accelerated CNC Machining, Metrology, and Manufacturing Technology program, will help you reach your career goals even faster, in just 22.5 weeks.

Are you ready to get your career in precision machining started? Click here to request more information, or call Goodwin College at 800-889-3282 to learn more.

Goodwin University is a nonprofit institution of higher education and is accredited by the New England Commission of Higher Education (NECHE), formerly known as the New England Association of Schools and Colleges (NEASC). Goodwin University was founded in 1999, with the goal of serving a diverse student population with career-focused degree programs that lead to strong employment outcomes.