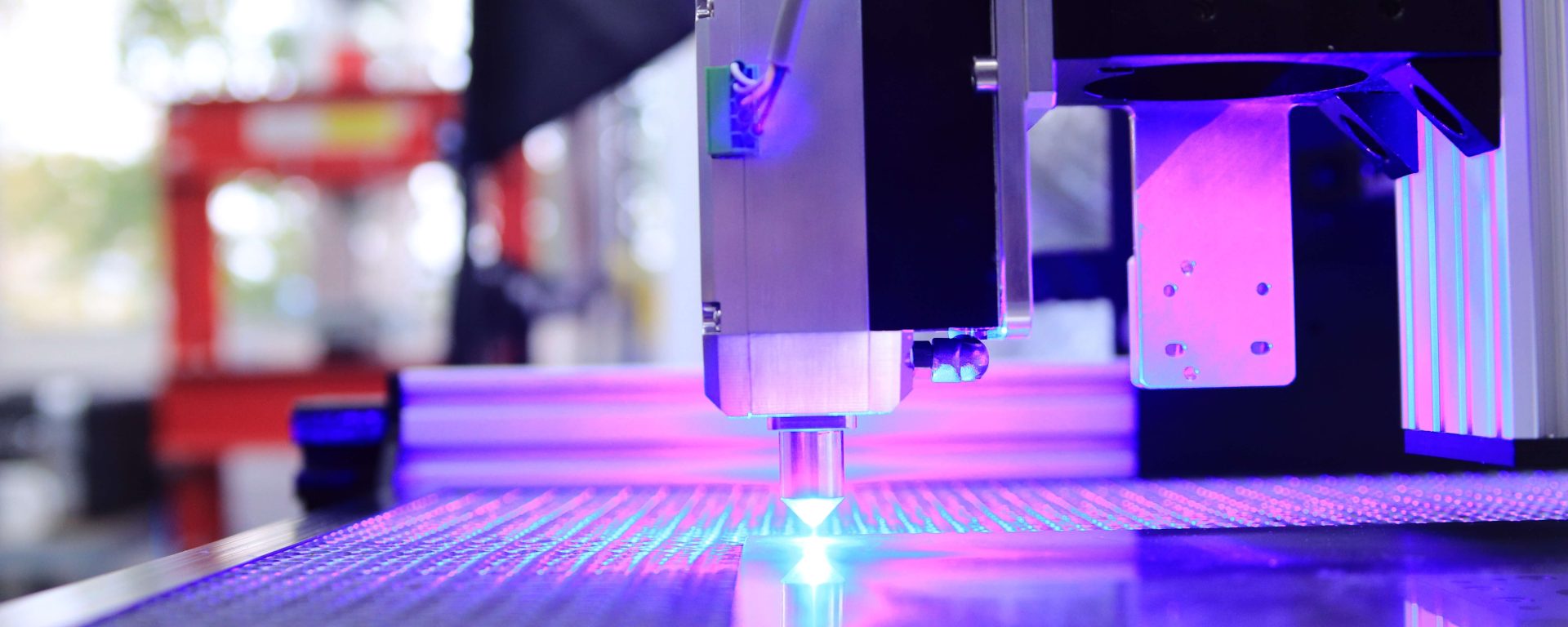

Assembly floors and manufacturing centers alike use Computer Numerical Control (CNC) machines to produce goods created through a replicable, cost-effective, and efficient process.

In today’s world, these machines are core pieces of technology for creating precision parts and products. While using these machines to fulfill complex tasks has reduced the need for human operators, skilled and qualified CNC operators are essential in ensuring the machines function, operate, and fulfill their purpose.

This article will explain what CNC automation is, what these machines can do, and where individuals passionate about machining fit into this ever-evolving field.

CNC Machine Automation

When first developed and introduced, CNC machines utilized punched or perforated paper tape for telecommunication data storage technology. Nowadays, they rely on digital instructions from computer-aided manufacturing (CAM) or computer-aided design (CAD).

Operated by a CNC machinist, these machines use these digital instructions in CNC machining language—called G-code—to interpret the designs, automate machine tools to simplify the production process, and, ultimately, reduce the intensity of the labor.

These types of machines are commonly used in metal and plastic part manufacturing plants, and their use comes with a variety of benefits, including:

- Efficiency: With their high degrees of precision, CNC machines reduce the waste from each workpiece and decrease production costs. They can also work at any time of day or night, given that they can continue operations without direct human intervention.

- Speed: Increasing efficiency directly affects the time it takes to finish production. By performing individual actions and combining other manufacturing steps, these machines work faster and quicker than human power alone.

- Consistency and Capacity: CNC machines produce identical products in higher quantities continuously, repeatedly, and identically, as long as there are no machine errors or breakdowns in the coding.

- Safety and Simplicity: They work independently, meaning once programmed, they will follow the instructions with only a few critical human operators to supervise and manage them. This also means manufacturing companies that use toxic or corrosive substances and high temperatures can keep employees safe by using CNC automation.

What Can Automated CNC Machines Do?

There are various types of automated CNC machines, and their specific abilities require different levels of automation, from simple to more complex.

Common types of CNC machines and their uses include:

- Milling Machines. As one of the most popular automated machines, CNC milling machines are highly precise machines that offer enhanced precision, repeatability, and the ability to produce complex shapes with tight tolerances. These machines allow for various operations like drilling, boring, slotting, and contouring, making them popular in the automotive, aerospace, electronics, and prototyping industries. Common types of milling machines include hand, plain, universal, and omniversal, with functions ranging from tapping, drilling, and turning to face milling and machine hard metals.

- Plasma Cutters. Designed to deliver highly accurate cuts of material with electrical discharge arcs, plasma cutters ionize the air and melt—or cut—the material where the torch strikes. Machinists use the hot plasma to cut through metal and for applications like industrial construction, restoration, and salvage operations.

- Lathe Machines. CNC lathe machines work best for cylindrical, conical, or flat products because they revolve around a central axis and use cutting tools applied to the workpiece to remove material and shape it into the desired product. Various metals, plastics, and wood are quickly transformed into everyday products like automobile parts, gun barrels, baseball bats, musical instruments, dining tables, and furniture legs.

- Waterjet Cutter. These versatile machines use high-pressure streams of water to cut through materials. They use a high-pressure pump to create high-speed water and sometimes add abrasive materials to the water to increase the cutting force. Stones, tiles, glass, metal, ceramics, plastic, foam, rubber, and other textiles can all be cut using a waterjet cutter automated CNC machine.

- Drilling Machines. Automated CNC drilling machines drill holes in any material for screws, secondary assembly, or aesthetic requirements. By using rotating drill bits to make cylindrical holes, these machines are utilized in the automobile, shipbuilding, astronautics, engineering, mold-making, and woodworking industries.

The level of complexity and automation needed for a CNC automation machine depends on the job or task, the accuracy required, the budget, and the time available for the job. CNC operators determine all these factors, the real-world problem solvers creating these innovative products and equipment.

Where Do CNC Operators Fit into the Evolving CNC Automation Field?

CNC machine automation is meant to streamline the manufacturing process. With the rise of combining this process with advanced robotics, we are closer to driving human-operated machinery off the manufacturing floor.

But CNC machines need machinists to implement and input the generated code and fix it if the code is incorrect or other system breakdowns occur. They must also be inspected for wear and tear and thermal expansion and adjusted for tolerance and performance.

Not to mention that with the advances in solid modeling, CAM/CAD systems, and computer integration, companies are ready to invest in trained machinists and robotic technicians.

Ready to learn what it takes to become a skilled CNC Machinist? Check our our CNC Machining Get Started Guide for a complete look at Goodwin’s CNC certificate and degree programs!

The CNC Machining Program at Goodwin University

If you’re interested in a hands-on, growing, and constantly changing field, look no further than a CNC automation operator and machinist career.

By earning a certificate or degree through a CNC Machining program, candidates can be integral in creating manufactured products and the booming manufacturing industry.

While every program will vary depending on the institution, our programs at Goodwin University combine classroom instruction and hands-on operation to instill the knowledge and machining experience needed to be successful in the industry.

Students receive an in-depth understanding of advanced Mastercam skills and a working comprehension of manufacturing mathematics required for programming tool location motion, feeds, and speeds—leading to competency in technical drawings, specifications, and computer-aided machining.

There’s no better time to enter this fast-growing industry. It all starts with a CNC Machining Program. Contact us today for more information.

Let’s crush your career goals together!

Goodwin University is a nonprofit institution of higher education and is accredited by the New England Commission of Higher Education (NECHE), formerly known as the New England Association of Schools and Colleges (NEASC). Goodwin University was founded in 1999, with the goal of serving a diverse student population with career-focused degree programs that lead to strong employment outcomes.