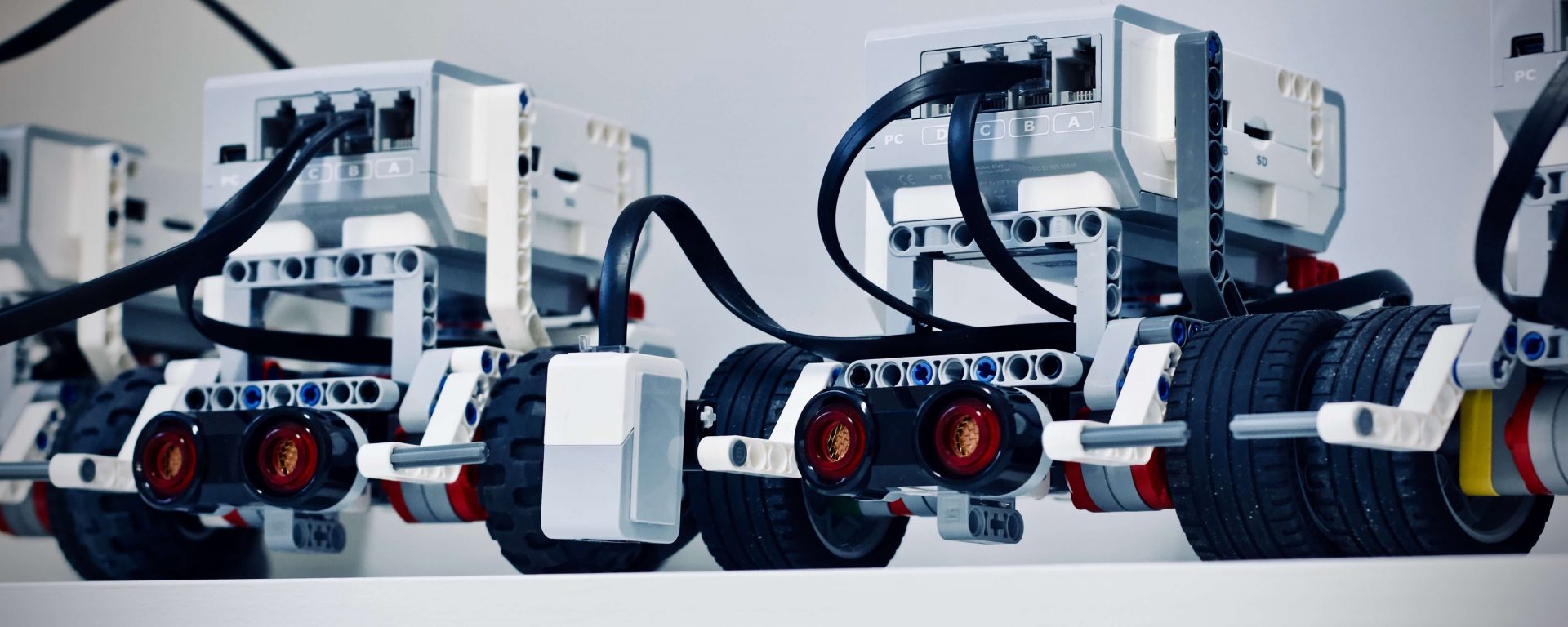

Manufacturing has come a long way over the years, with advanced technology paving the way for exciting innovations and occupations. Robotics and automation, for example, have significantly changed modern manufacturing processes, making them safer, smarter, and more efficient. At the same time, robotics has also led to many new, groundbreaking, and high-tech career opportunities. Robotics technicians are one popular example.

Robotics technicians are trained professionals that help to build, test, and maintain robotic equipment. To carry out their work, robotics technicians have in-depth knowledge of computer programming, motor control, and electrical schematics. If you are seeking a career that is forward-thinking, technology-driven, and hands-on, the robotics technician career path is one to consider.

What Does a Robotics Technician Do?

At a broad scale, a robotics technician is responsible for configuring, testing, operating, maintaining, and troubleshooting robots, as well as other automated systems used in production. Their primary goal is to increase the efficiency and prolong the life of robotic equipment. They work closely with robotic engineers to build and test new designs, in order to advance manufacturing and production processes.

The specific duties of a robotics technician can vary, depending on their employer and industry, as well as the types of robots with which they work. In general, however, a robotics technician can be found:

- Assisting in the construction of robotic equipment, collaborating closely with engineers

- Testing robotic systems to ensure they are working properly before use

- Installing and programming robotic equipment in a manufacturing facility

- Troubleshooting issues – both electrical and mechanical – that arise with robotics equipment

- Operating the equipment or overseeing the operation of robotics equipment

- Analyzing and categorizing events within the equipment

- Working closely with engineers and production team to help achieve a desired output

- Conducting preventative maintenance, such as routine upgrades and inspections

- Repairing robotic machines, systems, and tools as needed

- Disassembling (or re-assembling) robots to repair or replace defective parts

- Training others to install, use, and service robots

The Working Conditions of Robotics Technicians

Robotics technicians typically work within manufacturing facilities, but may specialize in a certain area of manufacturing such as aerospace, automotive, or medical device production. They may work on-site at production plants, in testing labs, or right in the operations of robots makers. Depending on where you work, the environment may differ. Testing labs are well-equipped, well-maintained, and generally well-lighted. Production plants may be noisier, but are very advanced and safe with proper PPE.

Overall, the career is known to have excellent job security, with robotics being a mainstay in the future of manufacturing. Robotics technicians typically work full-time schedules (about 40 hours per week), though some may work overtime. They also earn an excellent salary. According to the U.S. Bureau of Labor Statistics, mechanical engineering technicians earn over $63,000 annually, on average, nationwide. In Connecticut, however, the pay potential is higher, with the average technician earning almost $75,000 annually.

How to Become a Robotics Technician

As you can see above, the job duties of a robotics technician are comprehensive and computer-centric. Therefore, robotics technicians must be well-trained prior to launching a career. Generally, a postsecondary education and training program is recommended. This may be in a related field such as robotics and automation, electrical engineering, manufacturing technology, and more.

At Goodwin University, a leading school for manufacturing and machining, students have the option to pursue a postsecondary Robotics and Automation Technician Certificate. Just 24 credits, this program covers the core concepts of robotics and automation, and how they are applied to manufacturing, supply chain, retail operations, and more. Students gain a robust understanding of how to maintain, troubleshoot, and program automated systems and robots.

The program can be completed part-time or full-time, and can lead to a career as a robotics technician in just a short amount of time.

If you were asking, “What does a robotics technician do?”, and you have found that the answer aligns with your career aspirations, consider taking that next step. The education needed to land this cutting-edge career can be completed in just a matter of months.

As Camden West, a robotics technician, told the Bureau of Labor Statistics: “There’s always something new to learn, and it’s incredible what these companies have in terms of robotics. Take every opportunity you get to learn about robotics technology, because it’s the way of the future. And it’s a very entertaining career.”

Learn about Goodwin’s Robotics and Automation Technician certificate online here. You may also call us at 800-889-3282 to learn more about the program and career outcomes.

Goodwin University is a nonprofit institution of higher education and is accredited by the New England Commission of Higher Education (NECHE), formerly known as the New England Association of Schools and Colleges (NEASC). Goodwin University was founded in 1999, with the goal of serving a diverse student population with career-focused degree programs that lead to strong employment outcomes.