How Goodwin University’s School of Business, Technology, and Advanced Manufacturing Produced Masks, Shields, and a Sense of Community

On a Sunday afternoon in mid-March, 2020, just as the COVID-19 pandemic was tightening its grip on Greater Hartford, Dr. Cliff Thermer, Dean of Goodwin University’s School of Business, Technology, and Advanced Manufacturing, received a call from Dr. Maria Ellis, president of the Board of Trustees. She alerted him to the local depletion of available N-95 masks and asked if Advanced Manufacturing could help.

That conversation planted the seed for good deeds to come and joined several affirmative plans in progress at Goodwin. The University had recently donated a series of personal protective equipment (PPE) supplies to local healthcare facilities, and faculty and staff were anxious to do more. “Dozens and dozens of people across the University’s landscape were involved,” Thermer detailed.

Goodwin Community Unites to Respond

Goodwin’s Senior and Presidential Cabinets discussed how the institution could help with the mask shortage, passing along relevant articles for careful consideration. Administrative assistants researched project materials and 3D printer prototype codes. Provost and Dean of Faculty Dr. Danielle Wilken connected the School of Business, Technology, and Advanced Manufacturing to Dr. Chris Wiles, a resident physician associated with Hartford Healthcare, designing 3D masks from his dining room table.

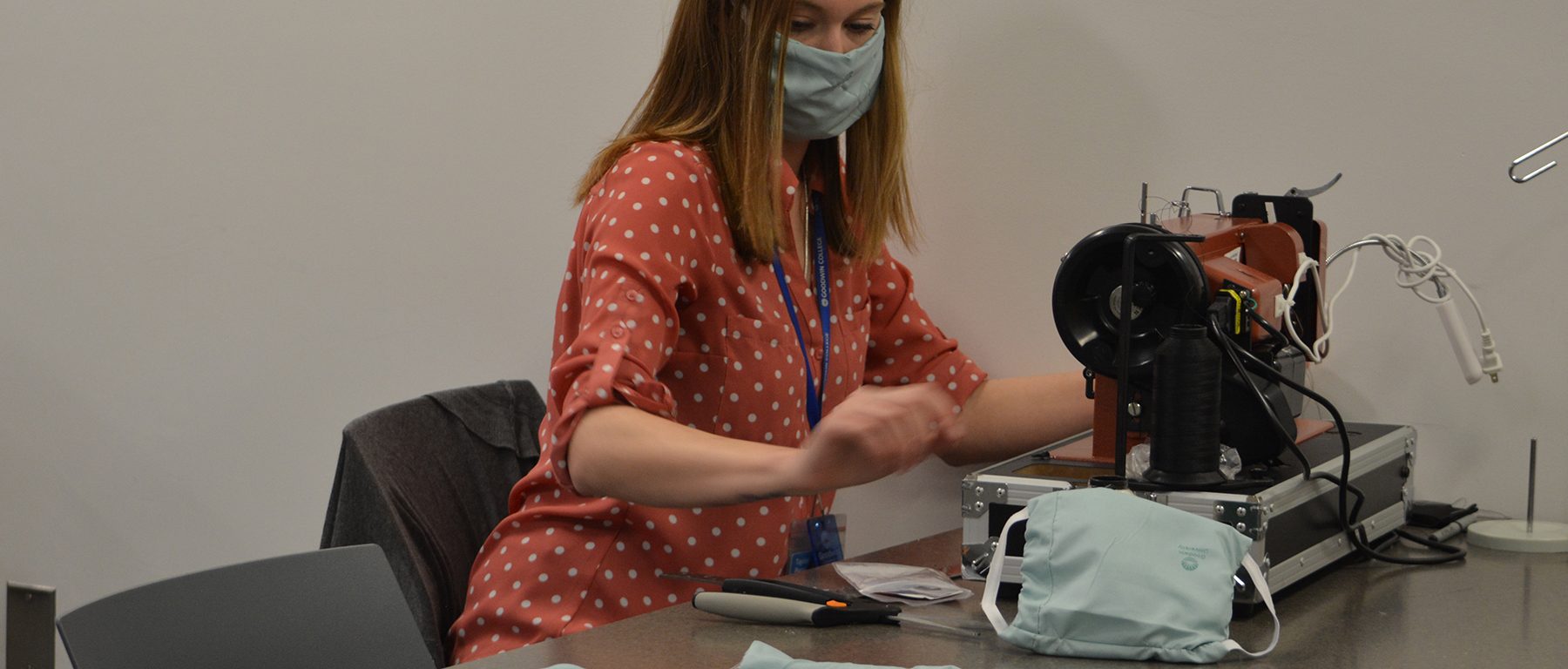

When Goodwin Quality Lab technician Taylor Perry wanted to add her talents to making an even greater difference, she started to sew cloth masks, stationed by the lab’s large window, directly across the hall from Pratt and Whitney’s Composite Center. When employees there saw Perry sewing away, they came in to ask what she was doing. Soon after, Pratt and Whitney offered the use of their 6’ X 10’ Gerber fabric cutting system and suggested using their 2’ fabric welding heat sealer for fusing polyester fibers to filters for an airtight alternative to sewing.

Also fabricated were 50 cloth masks made of cotton and HEPA filters. Designed by Perry through trial and error using a pattern she found on the internet, the masks contain a convenient, removable center filter. She used some of her own funds to buy the fabric and screens and worked on the two commercial sewing machines in Goodwin’s Quality Lab.

Ellie Pelletier, previously a professional seamstress and now a senior administrative assistant at Goodwin, left the confines of her home to help Perry work on creating more cloth masks. Together, they produced and distributed the protective equipment to the partners at Pratt and Whitney. Several dozen masks were also allocated to the remaining essential workers on Goodwin’s campus.

And the production continues. An influx of information on producing PPE arrived from Goodwin employees eager to lend a helping hand. From the abundance of ideas that filtered in, the Quality Lab team, led by lead technician Les Sinnock, selected the plans that could be authentically produced and put into action.

When Supply Shortage Meets Innovative Invention

“We’re not a manufacturer, we’re a school,” Thermer stated. “We teach students how to make things. But when called upon, we’re taking what we have, with the knowledge we have, driven by the technology available to us, and saying, ‘Hey, we can do this.’ Out of great need come great ideas, and to see that happening here at Goodwin with our partners and our people is really cool.”

The Masks of Small-Scale, Modern Manufacturing

In Advanced Manufacturing’s first round of supplies to fight the shortage on the frontlines, they’ve produced three different designs of masks — two 3D models, one cloth design, and an additional face shield.

Dr. Dusty Richardson, a neurosurgeon from Billings, Montana, recently designed the “Montana Mask,” which can be produced with plastic, sanitized for multi-use, with custom-cut filter inserts that override single-use disposal waste. Eighty masks of the Montana model were recently fabricated in Goodwin’s newly constructed, state-of-the-art Manufacturing Annex using 3D printers. The filter inserts are of MERV-13 grade, blocking impurities like dust, dander, bacteria, and most importantly, respiratory viruses like COVID-19. The tourniquet elastics that act as fastening straps were provided by Dr. Paula Dowd, Dean of the School of Nursing and Health Professions.

Dr. Wiles also designed a new mask model to be produced by the 3D printers. For enhanced safety precautions, he created frames for the covers that fit around the chin and nose to further protect the face. Essential Goodwin personnel received several masks, including front desk workers and Facilities staff. Goodwin lab techs continue to produce the 3D-designed masks. Once they are complete, the techs send them on to Dr. Wiles to pair with third-party filters fit to protect during the COVID-19 pandemic.

Fabricating a Safe and Reliable Face Shield

Twenty-five face shields were also Goodwin generated. Once the framing design was established, the Quality Lab tech team, including Tom Curry and Allan Nelson, had to find materials to make the shield. After several unsuccessful prototypes, acetate sheets, typically used for overhead projections, were chosen. Elastic tourniquets were used for the shield’s headband, and weather stripping, already on-hand at the University, was inserted for comfort.

The final masks and shields are then inspected, bagged, UV light treated, disinfected, and sanitized before being transferred to Hartford Hospital, Saint Francis Hospital, or UCONN Health Center, according to need.

Demand, Determination, and True Goodwin Grit

The goodhearted project and its much-needed persistence showed true Goodwin grit, as the 3D printers used are not industrial machines, but rather hobbyist printers that do not function at high speed. “While 3D technology is up and coming and some of the latest technology, it isn’t perfect,” Thermer explained. “I think some people have a Star Trek idea of 3D printers, that you can just walk up to them and say ‘computer print me…x’ and it comes out perfectly. But there’s still a process to it, and there’s still work and quality control involved.”

Quality Lab Techs Show the Value of Versatility

Faculty and staff making the masks and shields must still attend to their daily duties, adjusting to online instruction, making equipment training videos, and calling every individual student to keep up with routine wellness checks during social distancing.

On a mission to make a difference in our community, the Quality Lab tech team work in shifts to contest the catastrophic effects of the Coronavirus. “While the world was shutting down, everybody and all the pieces had to come together here to make this happen,” Thermer marveled. “And I’m proud to say that Goodwin is doing all we can to help.”

Update: As of April 28, 2020, the Goodwin team has produced 200 3D-printed masks, 40 face shields, and 105 CEGs (3D-printed frames to hold cloth masks tighter), which were sent to Hartford Hospital. They also cut more than 1,700 filters for masks, accomplishing in a few hours what otherwise would have taken five days to cut by hand. Currently in production are “ear savers,” which support the head straps on cloth masks. Cloth masks continue to be produced for distribution to Goodwin University and Pratt & Whitney workers.

Click here if you’re interested in learning more about how to innovate and inspire with Goodwin’s manufacturing degrees and certificate programs.

Goodwin University is a nonprofit institution of higher education and is accredited by the New England Commission of Higher Education (NECHE), formerly known as the New England Association of Schools and Colleges (NEASC). Goodwin University was founded in 1999, with the goal of serving a diverse student population with career-focused degree programs that lead to strong employment outcomes.