In recent years, the use of robotics has grown significantly throughout manufacturing, as AI and machine learning are integrated for more autonomous decision-making as well as increased efficiency and worker safety.

While some worry about the increased presence of robots in the workplace, rest assured that humans are equally important to carry out skilled trades. Even as the use of robotics grows, humans will still be needed to maintain, repair, and program such machinery. As such, Goodwin University’s Robotics and Automation Training Program is focused on preparing students for successful careers in robotics—teaching valuable skills that will lend well to the future of manufacturing.

Still, you may wonder about how robotics will impact manufacturing and its importance on the field as a whole. Below unpack the current landscape of robotics in manufacturing and explore what the future holds.

Importance of robotics in manufacturing

Students choose to study robotics more and more, as the use of robotics in manufacturing is constantly evolving to improve production processes. And with constant change, the job won’t ever get boring!

Initially replacing human labor for only the most repetitive tasks, robotics has evolved with technological advancements, incorporating AI and machine learning for increasingly autonomous decision-making. Those who work in robotics see many advantages to this evolution, making robotics an essential discipline for manufacturing professionals to understand.

Evolution of robotics in manufacturing

As mentioned, robotics in manufacturing began with its application in repetitive tasks, gradually expanding to more complex operations. Increasing advancements in the tech sector have played an important role, helping to integrate advances in AI and machine learning alongside robotics processes. These innovations have allowed robots to make autonomous decisions, improving both the quality and speed of manufacturing.

Advantages of integrating robotics into manufacturing processes

Integrating robotics into production operations results in higher production and efficiency, as robots can work continuously without becoming tired. Plus, automation reduces the margin of error by ensuring consistency in quality and precision.

By tackling dangerous jobs, robots lower labor costs and improve worker safety. Because of their versatility, robots allow manufacturing systems to adjust to production requirements quickly.

Examples of successful robotics implementation

Several industries have incorporated robotics into production processes, proving its effectiveness. Robotic arms are widely used in automobile assembly duties, leading to improved precision and faster production.

Similarly, automated procedures like testing, packing, and soldering have greatly increased dependability in the electronics manufacturing industry. Additionally, robotics are used in food processing to decrease waste and ensure hygienic requirements are met during the sorting, packing, and palletizing processes.

Across industries, manufacturing processes find creative ways to use robots for efficiency, quality, and safety.

Impact of robotics in manufacturing

Recent advancements in robotics technology have started a new wave of innovation, reshaping manufacturing practices across industries. These advancements have revolutionized traditional production processes, from integrating artificial intelligence (AI) to the development of collaborative robots (cobots).

Defined by the combination of AI and machine learning, the latest robotics technology enables robots to make autonomous decisions. Additionally, collaborative robots, or cobots, can work alongside humans by enhancing efficiency and safety. Advancements in sensors and vision systems have improved perception and decision-making, while cloud computing and data analytics allow for real-time monitoring and optimization.

These advancements have led to increased automation of complex tasks previously considered unsuitable for robots and improved production lines into more flexible and adaptive setups. Workers are given tools for remote monitoring, programming, and maintenance, creating new job roles focused on robot programming, data analysis, and system integration.

Forecast for the future of robotics in manufacturing

With ongoing expansion across industries, including small and medium-sized organizations, the future of robotics in manufacturing is bright. New fields, including biomanufacturing, nanotechnology, and 3D printing, will all use robotics.

Expanding safe human-robot interaction in shared workspaces would enable fully autonomous manufacturing facilities with low human intervention. However, potential societal effects, such as retraining the workforce and the ethical issues that arise with AI-driven decision-making, must be carefully analyzed.

The most recent advancements in robotics tech are changing production processes by increasing productivity, adaptability, and safety—developments that highlight how robotics in manufacturing is always evolving.

Goodwin’s Robotics and Automation program

Founded in 1967, Goodwin University is located in East Hartford, Connecticut. Accredited by the New England Commission of Higher Education (NECHE) and affiliated with the Connecticut State Colleges and Universities (CSCU) system, Goodwin University is dedicated to providing accessible, career-focused education to a diverse student population. As such, the university has a Robotics and Automation program designed to give students the skills and knowledge needed for success in an increasingly-demanded and valuable field.

The extensive curriculum covers key subjects such as industrial robotics applications, programming languages like Python and C++, automation systems, robotics basics, and control systems. The curriculum incorporates laboratory exercises and projects into the learning process, emphasizing practical experience.

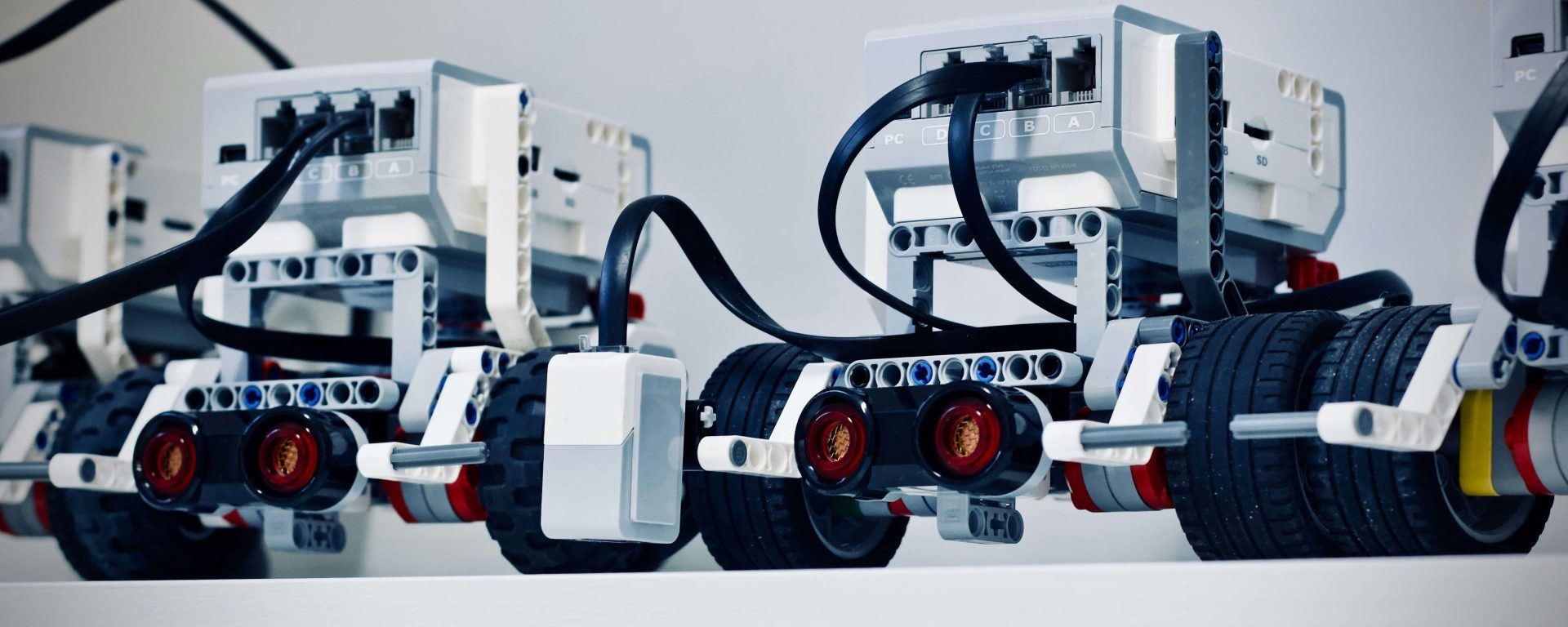

Faculty’s experiences are important for the program, with knowledgeable instructors leading the way. These faculty members bring engineering, robotics, and automation backgrounds to the classroom and engage in research and industry collaborations. The university has state-of-the-art labs to provide students with cutting-edge resources, including robotic arms, programmable logic controllers (PLCs), simulation software, and industrial automation systems.

Notable achievements within the program

Recognized for its unique curriculum and industry training programs, Goodwin students showcase their skills and knowledge in regional robotics competitions, putting Goodwin’s program a step above the rest.

Plus, collaborations with nearby manufacturing firms offer students and graduates opportunities for co-ops, internships, and job placements, providing smooth transitions into a career after graduation. The program is dedicated to progressing the industry with faculty-led research projects on industrial automation optimization, robotic vision systems, and autonomous automobiles.

Robots have advanced dramatically in manufacturing, and our Robotics and Automation Certificate Program is evolving alongside the industry, equipping students with a thorough education and practical experiences for successful employment after graduation. Apply to Goodwin University today!

Goodwin University is a nonprofit institution of higher education and is accredited by the New England Commission of Higher Education (NECHE), formerly known as the New England Association of Schools and Colleges (NEASC). Goodwin University was founded in 1999, with the goal of serving a diverse student population with career-focused degree programs that lead to strong employment outcomes.