As the field of manufacturing evolves, industry leaders look to qualified professionals willing to rise to challenges and adapt to new technologies.

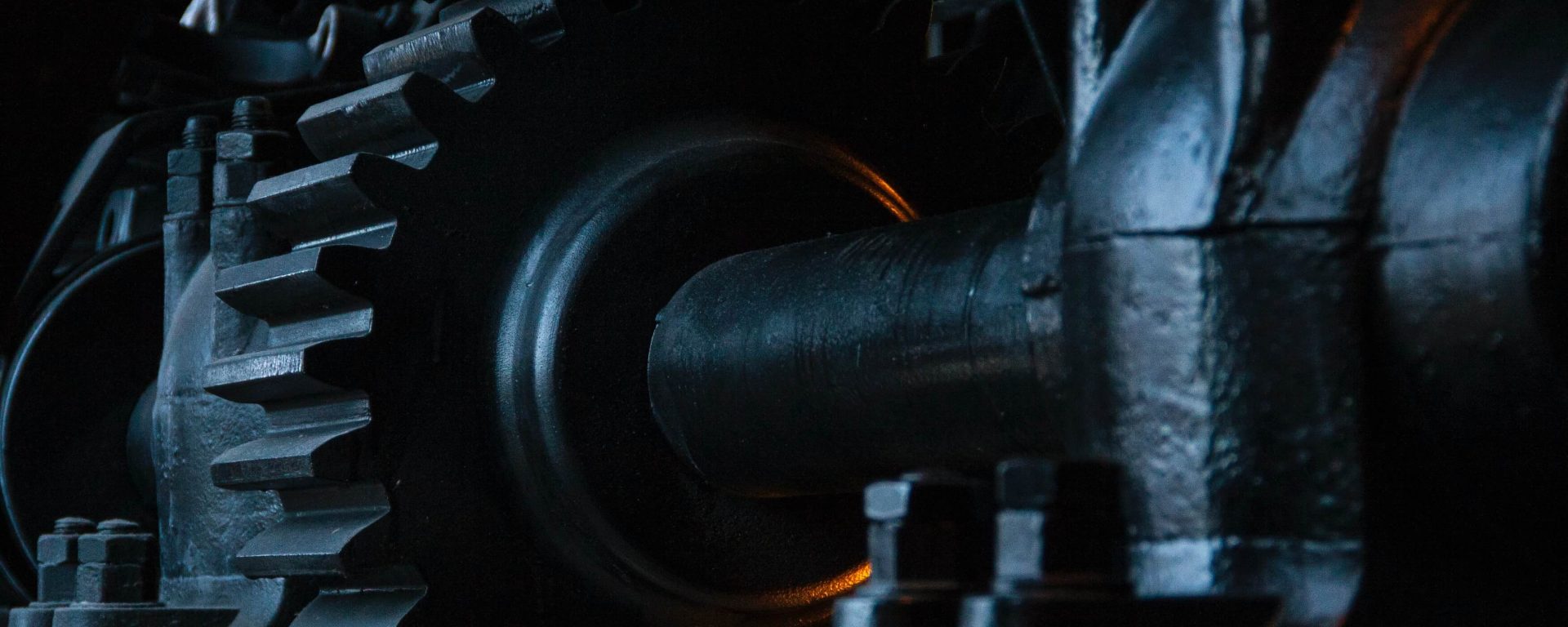

A commonly used machine, Computer Numerical Control (CNC), helps to make many durable goods like aircraft, artificial joints, and cars. But, these machines do not operate themselves.

This is why the manufacturing industry relies on skilled manufacturing technicians and machinists to operate these machines.

This article will explore five types of CNC machines, how they are used, the importance of these machines, and how students can prepare themselves for this exciting and integral career in the manufacturing industry.

What is CNC machining?

Computer Numerical Control (CNC) machining is an automated subtractive manufacturing process where an object is shaped by removing material from a workpiece until the desired shape is achieved. This process utilizes computerized software to control how the machines move and operate.

These machines use an algorithm written by designers to instruct the machine tools where to move and how to operate and control other secondary processes.

This process allows CNC machining and the machinists who operate them to deliver superior versatility, efficiency, and precision to make anything from small electronic components to large-scale aircraft and aerospace parts.

To learn more about a career in CNC Machining, download our CNC Machining Get Start Guide today!

Five Types of CNC Machines

CNC machines range from small mills and lathes utilized by small machine shops and trade schools to massive, high-powered units with multiple devices working across three, four, and five-axis ranges.

1. CNC Milling Machine

As one of the most popular CNC machines, CNC mills are primarily used for milling, drilling, and cutting operations.

They derive and convert specific programs of letters and numbers, known as G-code, to route and path the spindle differently. Then, the computer takes over once the workpiece is placed inside the milling machine.

Common types of CNC milling machines are hand, plain, universal, and omniversal and include functions like tapping, drilling, turning, and face milling to machine hard metals. Most of these machines have three-axis movements, but more advanced models can accommodate additional axes.

2. CNC Plasma Cutters

CNC plasma cutting machines deliver highly accurate cuts using an electrical discharge arc—such as a plasma torch—to ionize the air and melt the material where the torch strikes.

Since they work on an electric discharge mechanism, plasma cutters can only be used for machining electrically conductive materials. Businesses in automobile manufacturing, automotive repair, shipbuilding, fabrication, and salvage and scraping utilize CNC plasma cutters.

3. CNC Lathe Machines

Unlike CNC mill machines that can work on products of any shape, CNC lathe machines work best for cylindrical, conical, or flat products.

They work by revolving the workpiece material around a central axis and using the cutting tools applied to the workpiece to remove material and shape it into the required product.

Processes like cutting, sanding, facing, drilling, turning, and knurling are ideal uses for CNC lathe machines. Additionally, machinists use these machines to make the following items:

- Camshafts

- Automobile parts

- Gun barrels

- Crankshafts

- Baseball bats

- Musical instruments

- Dining tables

- Furniture legs

4. CNC Laser Cutting Machines

Like CNC plasma cutters, CNC laser cutters can cut through many materials, such as plastic, paper, fabric, metals, and hardwood.

Unlike plasma cutters, laser cutters use a powerful beam of highly focused light (aka a laser) to perform this task and have a smaller point of contact and spread, leading to a higher accuracy level and better surface finish.

Aerospace parts, automobile frames, medical equipment, and engraved materials are manufactured using CNC laser cutters.

5. CNC Drilling Machine

Another prevalent type of CNC machining is the CNC drilling machine. As the name suggests, it is used to drill holes in any material for screws, secondary assembly, or aesthetic requirements.

These machines use rotating drill bits to make the cylindrical holes in the workpiece, including spotting drills, peck drills, screw machine drills, and chucking reamers.

CNC drilling machines are utilized in the following ways:

- Automobile manufacturing

- Shipbuilding

- Astronautics

- Engineering machinery

- Mold making

- Woodworking and furniture making

Though these are some of the most common CNC machines, there are many others, and the choice of machine depends on the job, the accuracy required for that job, the budget, and the time available to complete the job.

And all that is determined by trained professionals and industry experts who spend time in CNC machining degree and certificate programs. Students in these programs learn how to design and create technical drawings, write efficient digital programming code, and operate different types of CNC machines.

CNC operators are real-world problem solvers creating products and innovative equipment, and this rewarding career starts with a CNC machining program.

CNC Machining at Goodwin University

At Goodwin University, we offer both certificate and associate degree programs in CNC machining. Both integrate and focus on providing students with an understanding of the manufacturing processes, knowledge of materials, and a working comprehension of manufacturing mathematics.

In addition to classroom instruction, our students get essential, hands-on operational experience with our new CNC 3-axis milling and turning machines to provide them with the knowledge and machining experience they need to have a successful and rewarding career.

Lastly, with our flexible scheduling, support services, and various financial aid opportunities, students know that we design our degree programs with their personal and professional livelihoods in mind.

Learn more and gain the skills you need to secure in-demand work in the growing field of CNC machining!

Goodwin University is a nonprofit institution of higher education and is accredited by the New England Commission of Higher Education (NECHE), formerly known as the New England Association of Schools and Colleges (NEASC). Goodwin University was founded in 1999, with the goal of serving a diverse student population with career-focused degree programs that lead to strong employment outcomes.