What Is the Most Important Information in a Blueprint Title Block? The Debate Rages…

by Kyle Zachary, MSOL, Continuing Education Instructor, Goodwin University

Blueprints, technical drawings, engineering drawings… whatever you call them, they are packed with critical information and are the most clear, concise expression of your clients’ needs. The lines, symbols, notes, and tolerances are your map to meeting the clients’ specifications. They help clients communicate their needs via specifications, and they help you and your company determine the most efficient ways to deliver those specs.

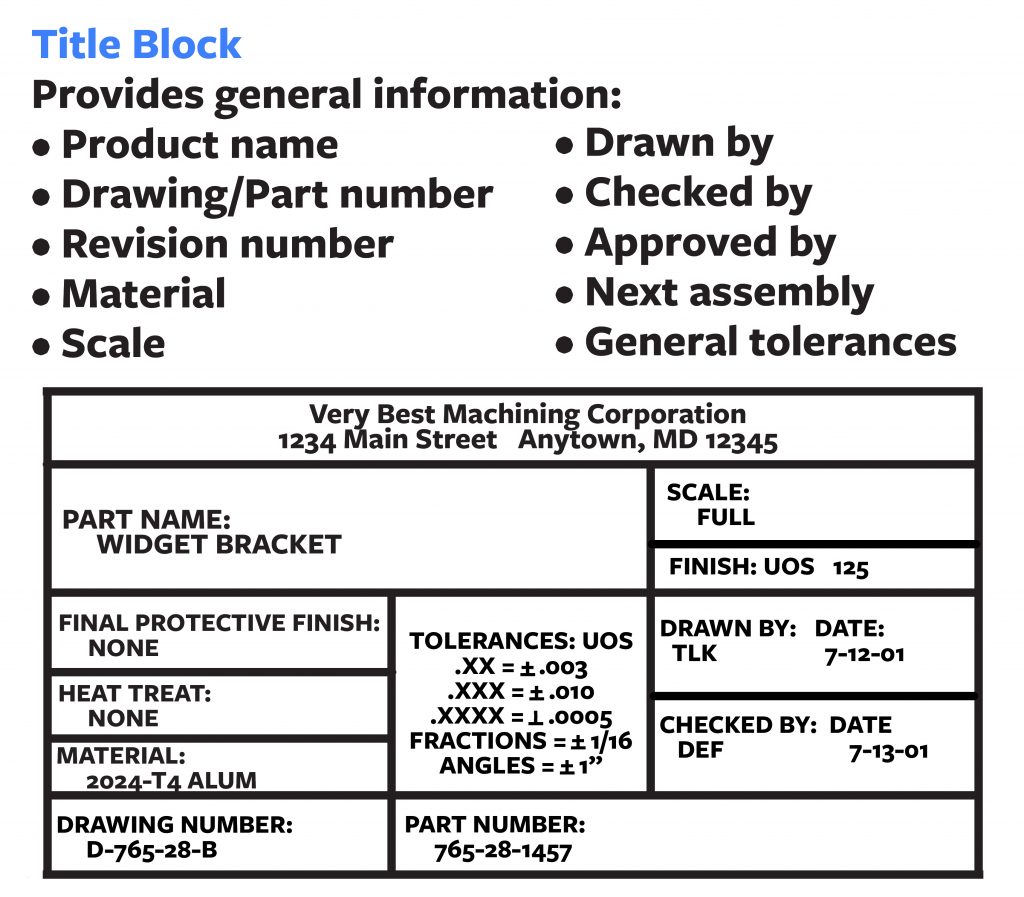

It’s obvious that good blueprint reading skills are essential to your individual success and the success of your company. When we teach the basic blueprint workshop at Goodwin University, one of the topics that inspire some interesting discussion is the title block. As students look at the following list of blueprint title block items, we ask them to consider: “What is the most important piece of information in the title block?”

Many items in a typical blueprint title block are only of limited utility. Scale, while very useful to cartographers, navigators, architects, and builders, is just a little-used reference in precision manufacturing. The same can be said for sheet size, the letter that references the standard size sheet on which the drawing has been printed. Aside from indicating whether the print has been enlarged or reduced, this information has no use in day-to-day production routines. These items are easy to eliminate, but what about the others?

In surveying the class, it’s common to have five or six items identified as most important, often including “approved by,” “material,” “revision number,” “part number,” and “general tolerances.”

In more than four years teaching the blueprint course, I have always argued for the revision number as the most important single piece of information. If you’re making a part using an old revision number, you’re making scrap, and all of the other information in the title block is meaningless.

Most people generally agree with this, but I have engaged in lively debates at several companies. One class at an aerospace company was adamant about their choice for most important title block item, and by the end of the course convinced me that there was a “most important part B” answer to the question.

These workers were responsible for producing and testing many parts that were virtually identical except for tiny details not easily detected visually. A casual glance at a blueprint might not pick up the difference either. The only way these workers knew they were making the right part was to constantly check and confirm part numbers. In their world, the critical information from the title block to avoid making the wrong thing was part number, and the revision number became secondary.

By the end of the discussion, they had impressed upon me the essential nature of part numbers in their work process. This raises the broader point that production and quality processes differ greatly across — and within — companies. This is reflected in the different ways that blueprints are used as a tool that the contributes to the successful production of the client’s needs.

Goodwin University offers a wide range of workshops designed to strengthen companies competitive value. Click here to learn more about Goodwin’s Continuing Education and Manufacturing Worker Training Programs.

Kyle Zachary is a faculty member in Goodwin University’s School of Business, Technology, and Advanced Manufacturing. He has worked in the wood technology industry and financial markets. Kyle has been a full-time teacher for 10 years, teaching a diverse range of subjects from ESL to Manufacturing and Six Sigma, including teaching positions in the U.S. and Brazil.

kzachary@goodwin.edu