Pride in Producing Again: Constructing the Connecticut Manufacturing Comeback

Grant Gives Goodwin The Green Light

In an effort to reduce Connecticut’s manufacturing workforce discrepancy through education, on August 3, 2020, Goodwin University was awarded a subcontract from Hartford’s Capital Workforce Partners through a grant from the Department of Labor’s Apprenticeship Connecticut Initiative (ACI). The funds will support a much-needed manufacturing training program, pivotal to increasing industrial job placements across the state.

With workforce development a central focus of Governor Ned Lamont’s administration, local organizations like Capital Workforce Partners encourage future generations of Connecticut skilled workers by helping them prepare for employment in manufacturing professions.

To strengthen Connecticut’s manufacturing future, the grant will give students a roadmap to automation careers through alluring academic programs. Goodwin’s grant award of $202,500 will provide tuition and support services for 30 students in its Early College Advanced Manufacturing Pathway (ECAMP™). This program gives middle and high schools, like Connecticut River Academy, access to manufacturing equipment, professionals, programs, and top-notch training.

Utilizing Goodwin’s 60,000-square-foot Business and Advanced Manufacturing Center and Advanced Manufacturing Mobile Lab, the grant funds will also provide training and support to 15 adult students of the University’s Mechatronics and Industrial Automation program for the upcoming school year.

The grant awarded to Goodwin is one step in many production pipelines to revitalize Connecticut’s manufacturing industry. The monies will aid and educate workers of various ages seeking career success.

“This grant provides a fantastic opportunity for local high school students to earn certification in Advanced Manufacturing and to prepare for rewarding careers,” Matthew Dodona, Early College Advanced Manufacturing Director, stated.

“The mechatronics and automation fields are important to today’s advanced manufacturing infrastructure,” Clifford Thermer, Goodwin’s Dean of School of Business, Technology, and Advanced Manufacturing, also made it a point to mention.

“Developing qualified persons in this field is critical to our state’s workforce and helping our manufacturers stay competitive. Manufacturing jobs allow participants to build sustainable careers, do work that matters, and control their financial destiny,” Thermer detailed.

The Current Career Shortage

Right now, manufacturing job retirements are on the rise, leaving tens of thousands of opportunities available in the state of Connecticut, but with insufficient numbers of skilled applicants to fill the abundance of job openings.

With around 150,000 Connecticut manufacturing jobs in limbo, five to ten percent of production workers retire annually. Meanwhile, Connecticut is only producing one to two percent of its replacements, leaving significant space for new learners to respond to the historic employment need and help revive the manufacturing industry.

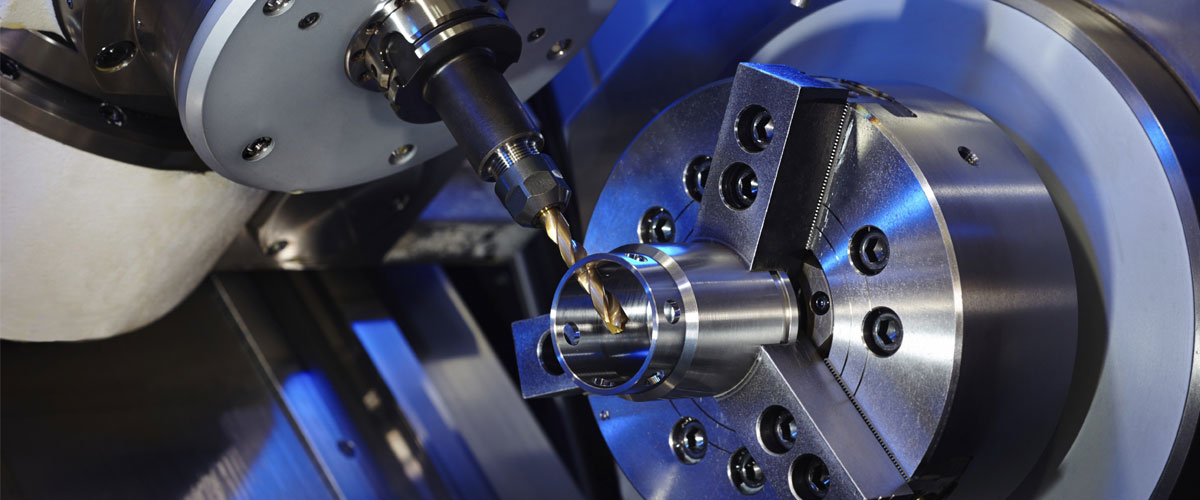

Once considered tough trades, modern technological careers have erased the days of dirty, unsafe assembly lines, and in their place ushered in a reinvigorated environment of robotics and computer-controlled systems of automation.

Goodwin is now gearing up to help secure Connecticut’s manufacturing future by providing a path for those interested in the field.

“High school seniors enrolled in ECAMP™ will acquire the skills needed to succeed in an Advanced Manufacturing career while fulfilling the Connecticut need for highly skilled CNC machinists,” Dadona further described.

Connecticut’s Productive Past

Once, the busy world of building in Connecticut was booming, with New Britain known as the “Hardware City,” and Waterbury the “Brass Center of the World.” Whether it was Bristol assembling locks and timepieces or Willimantic creating textiles, Connecticut made an early name for itself through its prosperous manufacturing industry.

In the 17th and 18th centuries, Connecticut provided produce, furs, timber, and iron for an international market. By the 19th century, mills and factories were creating fabricated textiles, tools, and cars to keep Connecticut’s commodities and goods thriving.

In 1914, the Great War in Europe caused international buyers to further spend within the states. The Cheney Brothers factory in Manchester, Connecticut, produced silk parachutes, and Goodyear made rubber boots and military tires in Naugatuck. While General Dynamics Electric Boat built submarines for the war effort in Groton, Pratt and Whitney made F-35 jet fighter engines in East Hartford.

So how did Connecticut go from being nicknamed the “Provision State” by George Washington to not producing enough workers to keep its factories running?

Maybe it was the myth that manufacturing jobs weren’t safe or stable livelihoods. Perhaps it was the offshoring of products to other countries. Or, it’s possible the Great Recession of 2007 could have been a correlation to the manufacturing workforce calamity. Somewhere along the line, children in Connecticut schools stopped considering manufacturing jobs viable careers that cater to their interests.

Creating the Foundation for Connecticut’s Manufacturing Future

In the eras before now, the Nutmeg State was a creative construction hub that many of us now call home. Now, if you drive past the abandoned, crumbling manufacturing buildings across Connecticut, you’ll seen firsthand how traditional manufacturing fields have fallen off. Many Main Streets seem more like ghost towns muddled in memories of what once was.

As the proud recipient of the apprenticeship grant, Goodwin University can now expand its efforts toward closing the Connecticut manufacturing workforce shortage by offering an abundance of training opportunities to assist students in transforming their production passions into successful, rewarding careers.

Are you interested in learning more about Goodwin’s Manufacturing degrees and certificate programs? Check out all the automation industry had to offer here!

Goodwin University is a nonprofit institution of higher education and is accredited by the New England Commission of Higher Education (NECHE), formerly known as the New England Association of Schools and Colleges (NEASC). Goodwin University was founded in 1999, with the goal of serving a diverse student population with career-focused degree programs that lead to strong employment outcomes.